Research

Novel fiber spinning technology

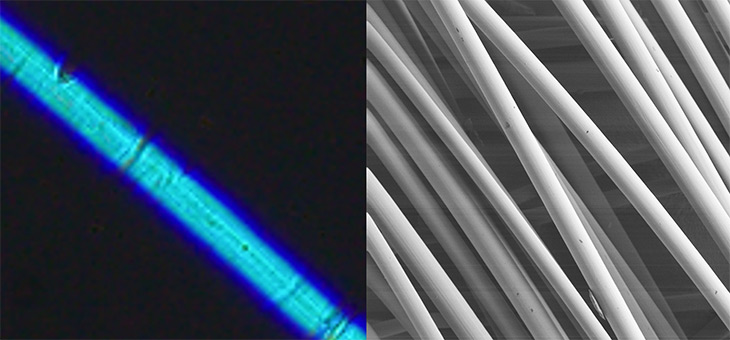

Our research in fiber spinning technology addresses the challenge of processing bio-based polymers, which often decompose before melting due to their non-thermoplastic nature. Traditional methods involve either chemically modifying these polymers to make them thermoplastic—compromising their biodegradability—or dissolving them using specialized solvent systems. We focus on the latter approach, which allows us to produce fibers with high mechanical strength while maintaining biodegradability. By exploring various dissolution and coagulation systems, and combining them with mechanical alignment techniques, we tailor the structure and properties of the regenerated fibers. Going beyond conventional chemical methods, we employ laser irradiation to modulate molecular interactions of polymer chains, pioneering a new fiber spinning technology that enhances both productivity and sustainability.

Smart fibers

Smart fibers are designed to react to external stimuli such as light, temperature, or pressure. By integrating specialized compounds during the fiber spinning process, we aim to incorporate functionalities directly into the fiber body to create materials that can change color, alter their properties, or even provide real-time data about environmental conditions. Our commitment to sustainability is reflected in our use of bio-based polymers as the substrate for fiber production, ensuring that our processes are environmentally friendly and contribute to a greener future.

Textile recycling

As global population and economic growth drive increased textile consumption, the challenge of managing textile waste becomes ever more pressing. In 2021, recycled textiles represented less than 1% of the global fiber market, highlighting significant opportunities for improvement in resource management and environmental conservation. Our research focuses on the upcycling of bio-based textile wastes, specifically cotton and wool fibers. We are investigating the use of ionic liquids to dissolve bio-based polymers, enabling the regeneration of fibers through spinning processes. This approach aims to transform textile waste into new, high-quality textiles, offering a sustainable solution to the growing issue of textile waste.

Bio-based composites

The growing demand for sustainable products highlights the critical role of renewable resources such as cellulose. However, relying solely on single-component polymers often limits material functionality and versatility. Our research seeks to overcome these limitations by developing composite materials that integrate various components to achieve enhanced properties. We address common issues such as phase separation and weak interactions between components by investigating the inter-component interactions and surface forces. For instance, we explore the use of genetically engineered bifunctional proteins to improve the interfaces between incompatible components, thereby enhancing the mechanical properties of the composites.

Rheology of bio-based polymers and colloids

We investigate a broad range of solvent systems to dissolve various bio-based polymeric materials. Controlling the rheological properties of these solutions is essential for optimizing the fiber spinning process and ensuring stable and continuous fiber production. By utilizing a comprehensive set of rheological tools, we aim to thoroughly understand the flow and deformation behaviors of these complex materials. Our research also extends to examining the rheological properties of bio-colloids, such as nanocellulose and protein suspensions. Our goal is to harness the potential of bio-based polymers and colloids to enhance material properties and refine processes for practical, real-world applications.